As a warehouse manager with over 20 years of experience, I’ve watched operations evolve the hard way. Manual labor, long shifts, constant pressure to move faster, and the daily challenge of keeping productivity up without burning people out. For years, we relied on forklifts, carts, and pure effort to keep things running. Everything started to change when we introduced autonomous mobile robots (AMRs) into our warehouse. What once felt like small operational improvements turned into a complete shift in how we work. At present, autonomous mobile robots are no longer optional. They are actively transforming warehouse operations from the ground up.

The Reality of Warehouse Operations Before Automation

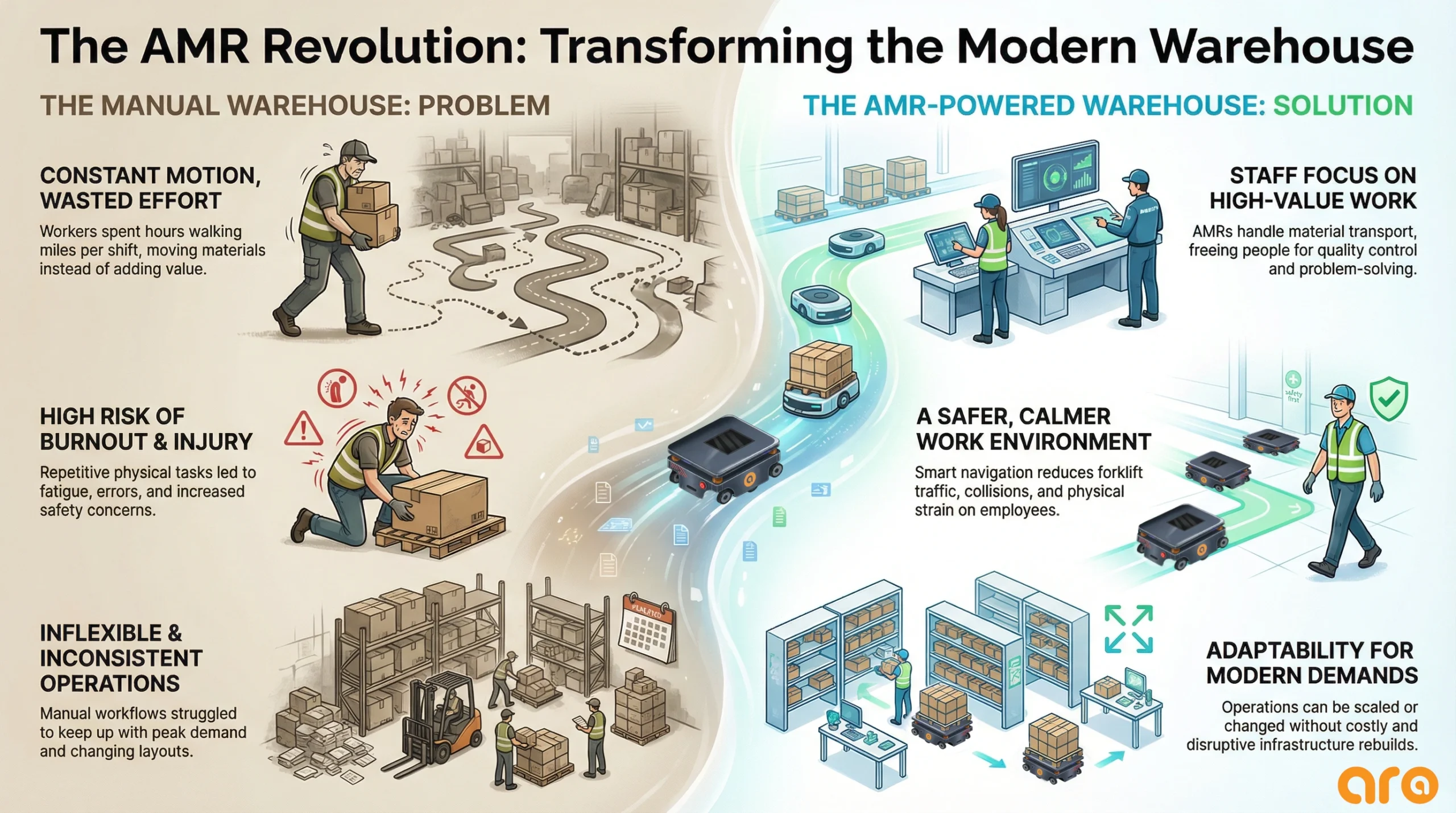

Before adopting AMRs, most of our time was spent managing movement rather than improving flow. Workers walked miles every shift moving materials between stations. Fatigue built up fast, and with it came errors, delays, and safety concerns. Even the most experienced teams slow down when tasks are repetitive and physically demanding. Manual labor made it hard to stay consistent, especially during peak demand periods.

The Hidden Cost of Repetitive Manual Work

Repetitive tasks don’t just affect productivity. They drain morale and increase the risk of injuries. Lifting, pushing, and rushing to meet deadlines creates strain that adds up over time. As a manager, I spent more time solving staffing gaps and fixing bottlenecks than focusing on long-term improvements. That’s where autonomous mobile robots started to make sense.

How Autonomous Mobile Robots Change the Way Warehouses Operate

Autonomous mobile robots (AMRs) are designed to move materials intelligently without fixed paths or constant supervision. Unlike traditional automation systems, they adapt to the warehouse environment in real time. They navigate safely, avoid obstacles, and integrate directly into daily workflows.

What Makes AMRs Different From Traditional Automation

Traditional conveyors and fixed systems lock you into one layout. AMRs don’t. They move where they’re needed, when they’re needed. That flexibility alone changes how warehouse operations are planned. Instead of redesigning the building around equipment, the equipment adapts to the operation.

Productivity Gains Through Smart Automation

One of the first things we noticed after introducing AMRs was how much time was wasted on simple transport tasks. Moving materials from receiving to production or from storage to packing added no real value, yet consumed hours every day.

Letting People Focus on High-Value Work

Once AMRs took over material movement, the team could focus on quality checks, coordination, and problem-solving. In our warehouse, our autonomous mobile robot, now handles material transport between workstations automatically. With a payload capacity of up to 120 kg and a runtime of around 7 hours on a single charge, our AMR works steadily throughout the shift without slowing down operations. The workflow became smoother, more predictable, and easier to manage.

Lower Operational Costs Without Cutting Corners

At first, investing in autonomous mobile robots looks expensive. I thought the same. But the long-term impact tells a different story. AMRs are energy-efficient, require minimal maintenance, and don’t rely on overtime or additional staffing to keep operations moving.

Smarter Maintenance and Fewer Disruptions

Modern AMRs come with predictive diagnostics that help identify issues before they cause downtime. That means fewer surprises and better planning. After integrating the AMR, we reduced our reliance on night shifts and overtime. Instead of stretching people thin, the robots kept production flowing consistently, which simplified scheduling and reduced operational stress.

Improving Safety Across the Warehouse Floor

Safety isn’t negotiable. Over the years, I’ve seen enough close calls to know how quickly things can go wrong. Heavy loads, forklifts, and tight deadlines create risk, especially when people are tired.

How AMRs Create a Safer Work Environment

Autonomous mobile robots are built with safety at their core. Equipped with LiDAR sensors and smart navigation systems, they detect obstacles, slow down around people, and avoid collisions. In our warehouse, once AMRs took over transport tasks, forklift traffic dropped significantly. The result was fewer near misses, less physical strain, and a calmer work environment where people could move safely and confidently.

Flexibility That Keeps Up With Changing Demand

Warehouse demand doesn’t stay constant. Seasonal spikes, new product lines, and layout changes can disrupt operations fast. Fixed automation struggles to adapt, but AMRs are built for change.

Scaling Operations Without Rebuilding Infrastructure

When we expanded into a new section of the warehouse, we didn’t need new conveyors or major construction. We updated the navigation maps for the robot, adjusted task assignments, and kept going. That level of adaptability is what makes autonomous mobile robots such a powerful tool for businesses looking to stay competitive.

Aro-S as Part of a Smarter Warehouse Ecosystem

Aro offers its AMR, Aro-S. From a management perspective, Aro-S doesn’t just add automation. It adds reliability. It moves materials consistently, integrates smoothly with our Warehouse Management System (WMS), and supports the team instead of replacing it. Over time, it becomes part of the operation rather than a separate piece of technology.

Consistency Is What Truly Transforms Operations

The biggest transformation isn’t speed alone. It is predictability. Aro-S doesn’t rush, doesn’t fatigue, and doesn’t introduce variability. That consistency allows a client to plan better, reduce stress on workers, and maintain steady performance even during busy periods.

The Future of Warehouse Operations

Automation isn’t a future concept anymore. It’s already reshaping warehouses everywhere. Autonomous mobile robots continue to improve with better batteries, smarter sensors, and more advanced navigation. As e-commerce and logistics demands grow, warehouses that delay automation will struggle to keep up.

The Bottom Line for Warehouse Managers

If your operation still depends heavily on manual labor for repetitive tasks, you’re limiting your potential. Autonomous mobile robots (AMRs) help reduce costs, improve safety, and boost efficiency while allowing people to focus on meaningful work. From my experience, adopting AMRs isn’t about replacing workers. It’s about empowering them. With solutions like Aro-S, capable of handling heavy loads and running reliably throughout the shift, warehouse operations become smarter, safer, and more sustainable. The transformation isn’t coming someday. It’s already happening on the warehouse floor.