Manufacturing industry needs to make and ship

Material Transport

Material handling operations traditionally consume about 25% of a factory’s workforce, occupy 55% of floor space, and account for 30–70% of the total cost of goods produced, showing how much internal transport can dominate costs and resources.

Background Manual Work

Let your team do what they are good at. Commonly, manufacture ring employees need to perform menial and labor intensive tasks which can be automated

Introduce our autonomous mobile robots

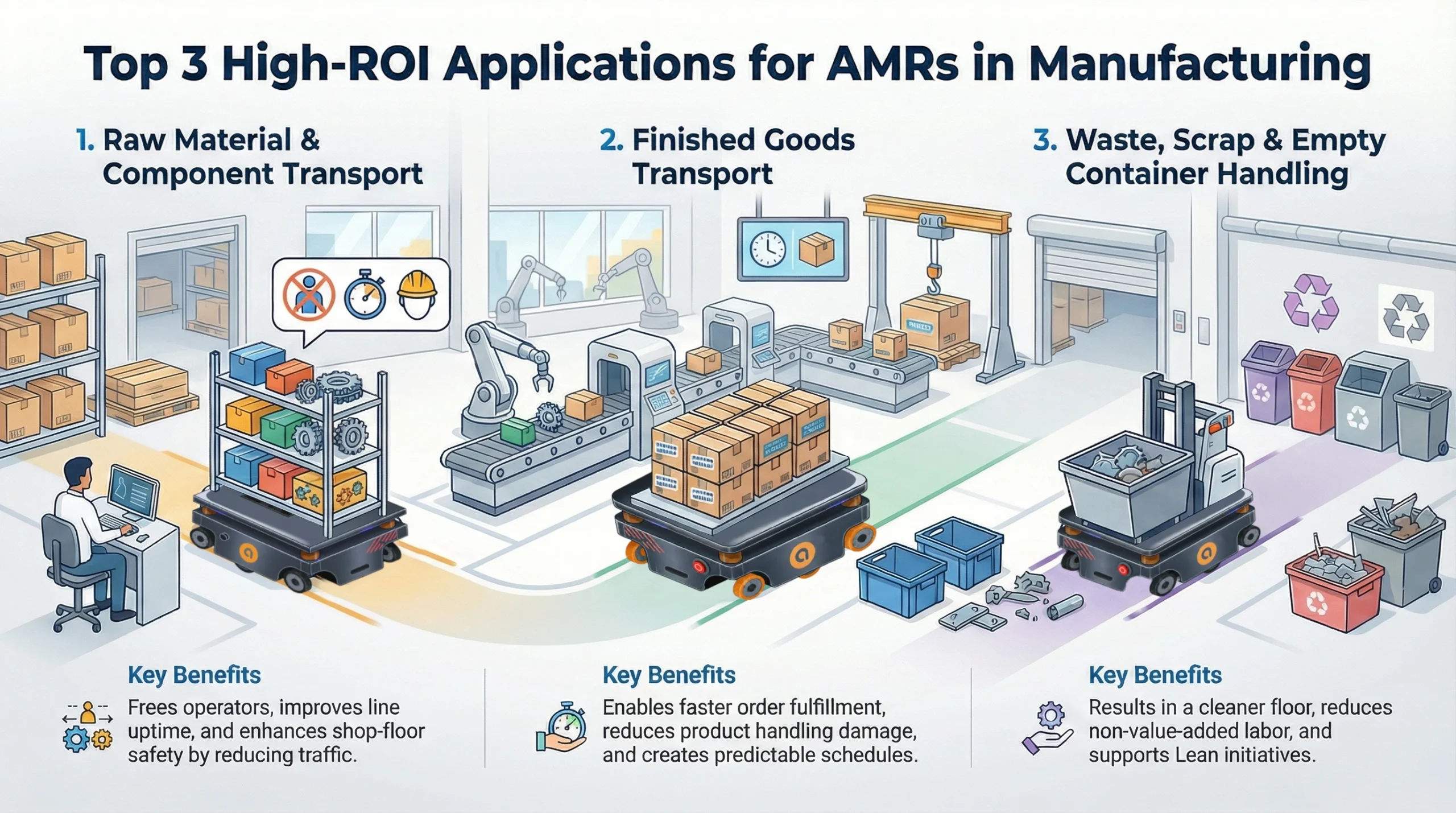

In a medium-sized manufacturing business (≈100–500 employees, single or multi-line facility), Autonomous Mobile Robots (AMRs) are most effective when applied to repetitive, high-frequency internal logistics tasks. The following three are the most common and highest-ROI candidates:

Material Transportation

AMRs move raw materials, components, and sub-assemblies from receiving or storage areas to production lines and between work cells.

Typical use cases

- Pallet, tote, or bin transport

- Line-side replenishment (just-in-time delivery)

- Inter-process movement in cellular manufacturing

Impact

- Frees operators from walking and driving tasks

- Improves line uptime and material availability

- Enhances shop-floor safety

Finished Goods Transport

AMRs transfer completed products from production lines to inspection, packaging, staging, and outbound docks.

Typical use cases

- Moving finished pallets to stretch-wrap stations

- Transporting cartons to quality inspection

- Dock staging for outbound shipping

Impact

- Faster order fulfillment

- Reduced product handling damage

- More predictable shipping schedules

Waste Handling

AMRs collect and return empty totes, pallets, bins, scrap metal, and packaging waste throughout the facility.

Typical use cases

- Returning empties to the warehouse

- Scrap removal from machining centers

- Cardboard and packaging waste transport

Impact

- Cleaner, safer shop floor

- Reduced non-value-added labor

- Better compliance with 5S / Lean initiatives